How to Select the Right Stainless Steel Coiled Tube for Your Projects?

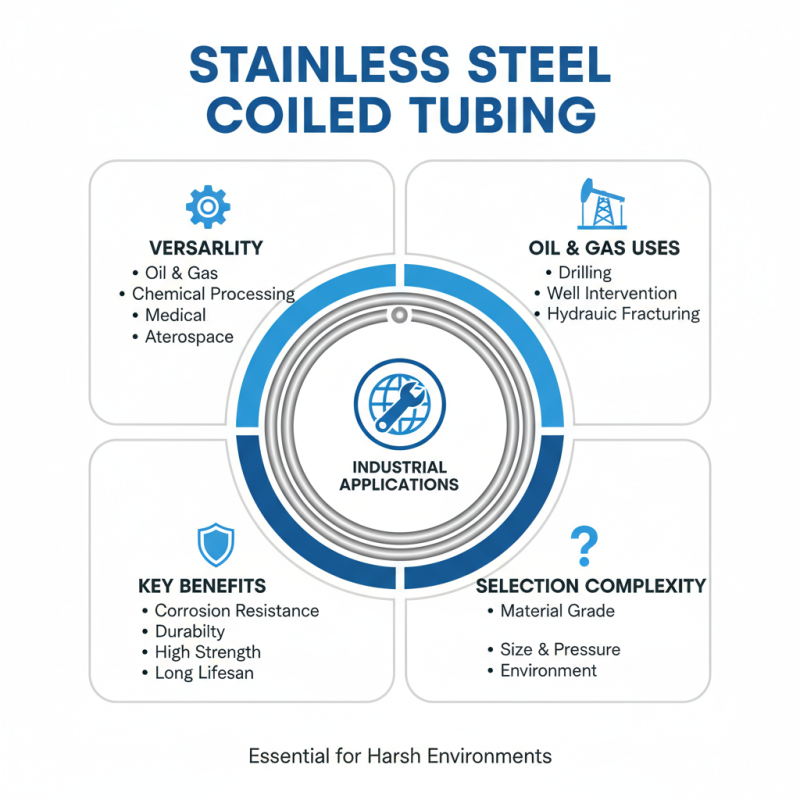

Selecting the right Stainless Steel Coiled Tube is crucial for various engineering projects. The global market for stainless steel tubing is projected to reach USD 20 billion by 2025, highlighting its importance. Stainless Steel Coiled Tubes offer excellent strength and corrosion resistance, making them suitable for a wide range of applications.

Yet, the selection process can be complex. Factors such as material grade, tube size, and application type must be considered carefully. A common mistake is underestimating the impact of proper specifications on project outcomes. Research indicates that 25% of engineers face challenges due to improper tube selection. Non-compliance with standards can lead to failures in critical systems.

Understanding the specific requirements of your project is vital. This includes the operating environment and fluid type. The right choice of Stainless Steel Coiled Tube can significantly enhance efficiency and longevity. However, lacking in-depth knowledge can lead to costly errors. Prioritizing informed decisions is key to successful project execution.

Understanding the Different Types of Stainless Steel Coiled Tubes

When selecting stainless steel coiled tubes, it's essential to understand the different types available. Stainless steel is valued for its strength and corrosion resistance. According to the GSCI report, the global demand for stainless steel tubing reached over 5 million tons in 2022. This figure indicates the growing reliance on stainless steel in various industries.

There are several compositions of stainless steel. Austenitic stainless steel is notable for its excellent durability and weldability. Meanwhile, ferritic stainless steel offers good resistance to stress corrosion cracking. A report from the Nickel Institute highlights that austenitic grades, like 304 and 316, are preferred in food and pharmaceutical sectors due to their sanitary properties. Each type has unique characteristics and applications.

Selecting the right type involves considering numerous factors. The environment of use can heavily influence your decision. For instance, while austenitic tubes are versatile, they may not perform well in extreme temperatures. Data from ASTM International suggests that tube thickness and diameter also play a critical role in performance. A mismatch can lead to inefficiencies. Understanding these details is vital.

Key Factors to Consider When Selecting Coiled Tubing for Projects

When selecting stainless steel coiled tubing for projects, several key factors should come into play. The application is crucial. Different projects require different specifications. For instance, the pressure and temperature ratings matter significantly. Understand the environment of use. Is it marine, chemical, or industrial? Each setting has distinct demands.

Material grades should also be taken into account. There are various grades of stainless steel. They differ in strength and corrosion resistance. Choosing the wrong grade can lead to premature failure. Cost is another factor to ponder. Higher quality tubing may come with a price, but it often saves money in the long run. Evaluate durability versus budget constraints.

Don't overlook the size and flexibility of coiled tubing. Smaller diameters are easier to handle but may not fit high-flow applications. Ideal lengths can also be challenging to find. Too short may affect performance. Too long may waste material. Reflect on previous projects. Consider past mistakes for better decision-making. A thoughtful approach ensures better outcomes in future selections.

How to Select the Right Stainless Steel Coiled Tube for Your Projects?

| Key Factors | Description | Recommended Grade | Typical Applications |

|---|---|---|---|

| Material Grade | The specific stainless steel alloy used affects corrosion resistance and strength. | 304, 316 | Food processing, chemical handling |

| Diameter | Outer diameter of the tube, important for fitting compatibility. | 1/4" to 2" | HVAC systems, automotive applications |

| Wall Thickness | Influences pressure rating and durability. | 0.020" to 0.120" | Oil and gas, water transport |

| Coil Length | Length of the coiled tube, affects installation and cost. | Up to 1000 ft | Custom fabrication, long runs |

| Bend Radius | Minimum radius the tube can be bent without kinking. | 5x diameter | Piping systems, aerospace applications |

| Temper | Heat treatment process that affects the mechanical properties. | Annealed, cold drawn | Industrial machinery, structural applications |

Assessing the Specifications and Standards for Coiled Stainless Steel Tubes

Choosing the right stainless steel coiled tube requires careful evaluation. Start by assessing the specifications based on your project requirements. Common standards include ASTM and ASME, which ensure safety and quality. Familiarize yourself with these documents.

When considering your project, think about the size and thickness of the tube. This affects strength and flexibility. You might want a thicker wall for high-pressure applications. However, too thick can limit bending capability. Balance is essential here.

Tips: Always double-check your specifications before purchasing. A small mistake can lead to significant issues later. Consult with experts if you're unsure. Don't overlook the material grade; it plays a crucial role in corrosion resistance and durability. Test samples when possible; they give practical insight into performance.

Evaluating Supplier Options for High-Quality Stainless Steel Coiled Tubes

When evaluating supplier options for stainless steel coiled tubes, several important factors come into play. Quality is paramount. According to industry reports, around 30% of issues stem from poor material selection. Coiled tubes need to efficiently withstand both pressure and temperature fluctuations. Look for suppliers who offer materials compliant with ASTM standards, which often leads to better durability.

Pricing can vary significantly. Some suppliers may provide lower prices but compromise on quality. It’s essential to analyze the cost-benefit ratio for your project. A report from the American Institute of Steel Construction shows that investing in high-quality materials can reduce long-term maintenance costs by up to 25%. Suppliers should ideally offer transparent pricing models that reflect their quality.

Supplier reliability is another crucial aspect. A recent survey indicated that nearly 40% of project delays are due to late or inconsistent deliveries. Reliable suppliers not only meet deadlines but also provide traceability for their products. Engaging with them directly about their sourcing and manufacturing processes can uncover potential risks. Effective communication with potential suppliers ultimately shapes the project's success.

Common Applications and Industries Utilizing Stainless Steel Coiled Tubing

Stainless steel coiled tubing is widely used across various industries. Its versatility makes it essential in sectors like oil and gas, where durability is crucial. In these fields, coiled tubing helps with drilling, well intervention, and even hydraulic fracturing. The resistance to corrosion allows these tubes to withstand harsh environments. However, selecting the right type can be complicated.

Another significant application is in HVAC systems. The coiled tubes assist in fluid transfer, ensuring efficient heating and cooling. These systems rely on reliable materials to maintain performance over time. In contrast, using subpar tubing can lead to failures and costly repairs. Thus, careful consideration is necessary when sourcing materials.

Additionally, coiled tubing plays a role in food processing. Its smooth surface prevents contamination, ensuring compliance with safety standards. While these applications showcase its importance, the decision-making process is complex. It’s easy to overlook factors like temperature tolerance and pressure ratings in the rush to procure materials. Reflecting on these aspects can lead to better choices in future projects.

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

WeChat

13295445693

-

Top