Why Choose ASTM A269 316 Coiled Pipe for Your Next Project?

When selecting materials for your next project, the choice of piping can significantly impact both performance and cost. ASTM A269 316 Coiled Pipe stands out for many applications. It offers excellent corrosion resistance, especially in harsh environments. With a smooth interior, it enhances fluid flow, reducing pressure drops.

Choosing the right pipe requires careful thought. One must consider factors like temperature, pressure, and environment. ASTM A269 316 Coiled Pipe is ideal for high-temperature applications. However, it may not be the best choice in every scenario. Understanding specific project needs is crucial.

ASTM A269 316 Coiled Pipe also provides flexibility due to its coiled design. This allows for easier installation in tight spaces. Yet, not all projects require such flexibility. In some cases, straight pipes may be more appropriate. Evaluating all aspects is key to making an informed decision.

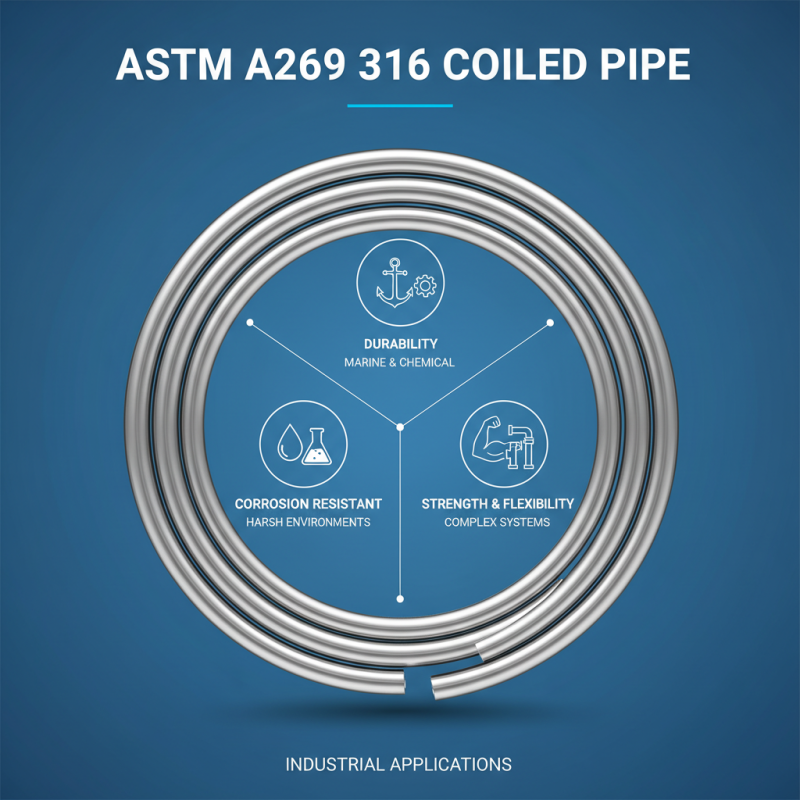

Understanding ASTM A269 316 Coiled Pipe and Its Specifications

ASTM A269 316 coiled pipe is a popular choice in various industries. Its specifications highlight its superior corrosion resistance. This makes it ideal for environments that face harsh conditions. Stainless steel 316 provides durability, particularly in marine and chemical applications. The pipe exhibits excellent strength and flexibility. This is vital when dealing with complex piping systems.

One notable aspect is the seamless design. This reduces the chances of leaks significantly. The coiled nature allows for easier transportation and installation. However, some may find it challenging to handle due to its weight. Additionally, the bending radius can be an issue in tight spaces. Custom lengths and diameters are available, but they may come at a premium cost.

Understanding these specifications is crucial. They determine the pipe's performance and longevity. Not every project requires ASTM A269 316 coiled pipe. Evaluating your needs is important. Are the project conditions suitable for its use? Scrutinizing the details can save time and resources.

Key Benefits of Using ASTM A269 316 Coiled Pipe in Different Industries

When it comes to choosing materials for various industries, ASTM A269 316 coiled pipe stands out. This stainless steel pipe offers significant corrosion resistance, making it ideal for environments exposed to moisture and chemicals. It is widely used in food processing, pharmaceuticals, and marine applications. The ability to withstand extreme temperatures without compromising structural integrity is also a notable benefit.

In food processing, cleanliness is paramount. ASTM A269 316 coiled pipe is non-reactive, ensuring that no contaminants leach into products. However, some installations struggle with proper sealing, leading to leaks. Identifying the right fittings can reduce this risk. In pharmaceuticals, where precision is key, this type of pipe's consistency helps maintain strict regulatory standards. Yet, installation costs can be high, warranting careful financial planning.

Marine applications benefit from the pipe's resistance to saltwater corrosion. Use in shipbuilding illustrates this. Still, industries must monitor maintenance actively to prevent long-term issues. Corrosion may develop in unexpected areas if not inspected regularly. Each sector has unique challenges, making it critical to analyze project needs thoroughly. Selection of materials should not be taken lightly.

Why Choose ASTM A269 316 Coiled Pipe for Your Next Project?

| Benefit | Description | Industries |

|---|---|---|

| Corrosion Resistance | ASTM A269 316 provides excellent resistance to corrosion in various environments, making it ideal for marine and chemical applications. | Chemical, Marine, Food Processing |

| High Strength | The material offers high tensile strength, which adds durability and longevity to the piping systems. | Construction, Oil & Gas |

| Versatility | This coiled pipe can be used in a variety of applications, making it a flexible choice for multiple projects. | Power Generation, HVAC |

| Ease of Installation | The coiled design allows for easier handling and installation, reducing labor costs. | Plumbing, Construction |

| Temperature Resistance | ASTM A269 316 can withstand a wide range of temperatures, making it suitable for diverse applications. | Chemical, Aerospace |

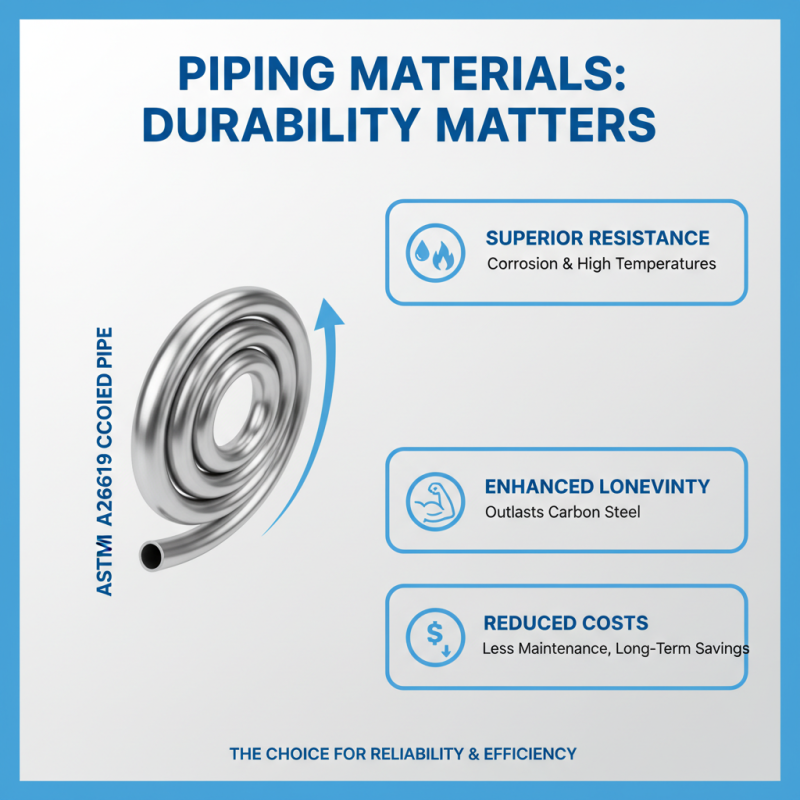

Comparative Analysis: ASTM A269 316 Versus Other Pipe Materials

When selecting materials for piping, durability matters. ASTM A269 316 coiled pipe stands out for several reasons. Its resistance to corrosion and high temperatures makes it a popular choice. Compared to carbon steel, it surpasses in longevity and reduces maintenance needs. This means lower costs in the long run.

However, it’s essential to consider other factors. For instance, while ASTM A269 316 offers great strength, it is more expensive than standard stainless steel. Some projects may benefit from more cost-effective materials, depending on their specific needs. Aluminum pipes can be lighter and easier to handle but fall short in strength and heat resistance.

In projects requiring high hygiene standards, such as food processing, ASTM A269 316 performs excellently. Its smooth surface prevents bacterial growth, unlike other materials. Yet, it might be overkill for less demanding applications. The decision should carefully weigh performance, cost, and specific project requirements. Each material has strengths and weaknesses; reflect on your unique project needs before committing.

Application Areas: Where ASTM A269 316 Coiled Pipe Excels

When considering the use of ASTM A269 316 coiled pipe, its application areas stand out. This type of stainless steel is widely used in various sectors, such as food processing and pharmaceuticals. Its resistance to corrosion makes it ideal for environments dealing with harsh substances. In food plants, the cleanability of this pipe ensures safety and hygiene. The same applies to pharmaceutical manufacturing, where precision matters greatly.

The versatility of ASTM A269 316 coiled pipe extends to the chemical industry too. It can handle different chemicals without degrading. This durability is essential, especially in processes that require transporting hazardous materials. Some may overlook the importance of material choices, leading to failures in production. Such mistakes can be costly and inefficient.

In building and construction, this coiled pipe serves structural needs as well. Its strength and flexibility allow for innovative designs. However, project managers must consider proper installation techniques. Missing these details can lead to issues later on. Thus, while ASTM A269 316 coiled pipe excels in various areas, reflection on its application is vital.

Factors to Consider When Choosing ASTM A269 316 Coiled Pipe for Projects

When selecting ASTM A269 316 coiled pipe for your project, several factors demand attention. Corrosion resistance is essential. This grade provides durability in harsh environments. It is ideal for chemical processing and marine applications. Evaluating the environmental conditions prior to selection is crucial. The pipe should withstand the specific elements it will face.

Another important consideration is the pipe's size and flexibility. Coiled pipes offer ease of installation. They can navigate tight spaces more easily than straight pipes. However, proper dimensions must be confirmed. Misjudgments in size can lead to installation issues. The bend radius and coiling must meet project requirements thoroughly.

Lastly, consider the mechanical properties. ASTM A269 316 offers good strength and tensile properties. However, not all projects require high strength. Balancing cost with material properties can be tricky. Analyzing project needs and budget constraints is vital. Sometimes, a more cost-effective solution may yield satisfactory results.

Comparison of ASTM A269 316 Coiled Pipe Properties

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

WeChat

13295445693

-

Top